R. P. Engineering (P) Ltd. has been a professionally managed manufacturer of Forged Carbon Steel Flanges, Butt-weld, Socket weld, Screwed Pipe Fittings, Railway Forged Components, Ring Joint Gaskets, Stud & Nuts, Various Forging Components, Open & Close Die Forgings to a wide range of sizes and classes.

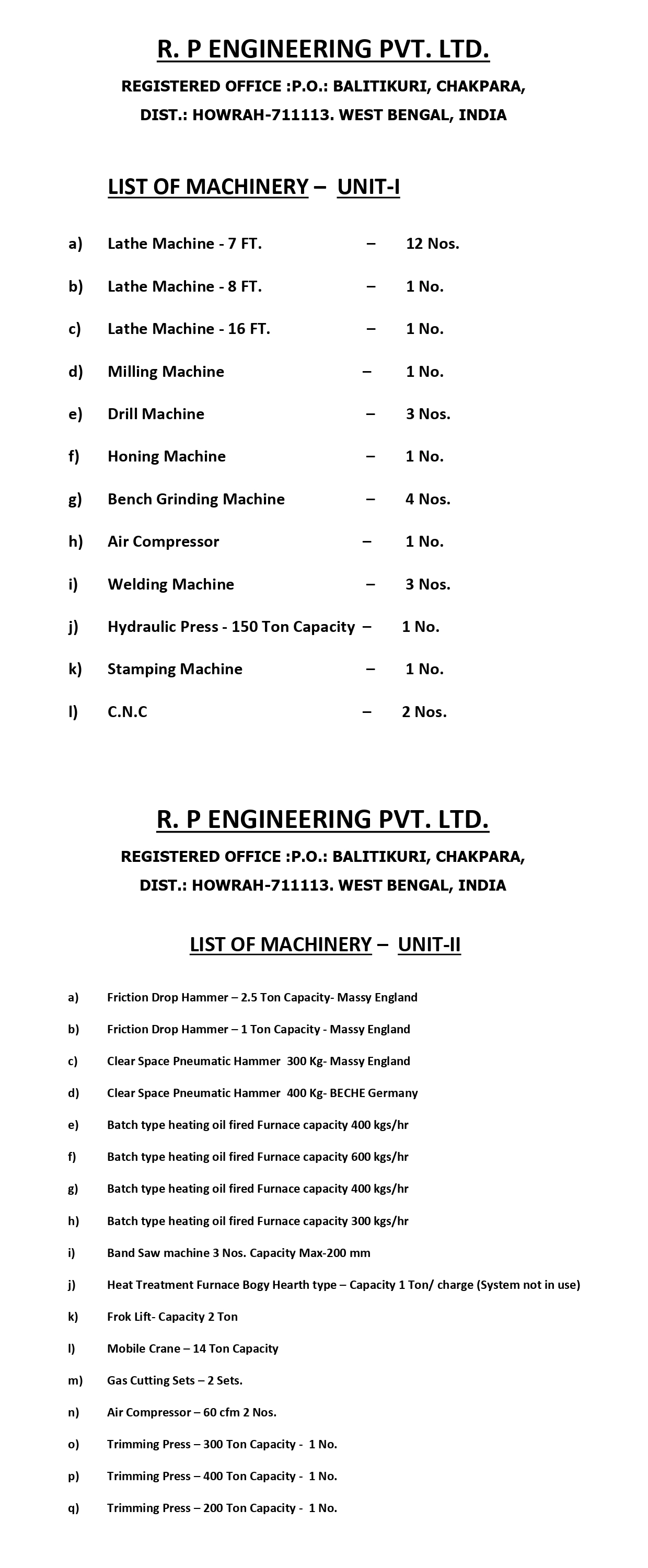

Our Forging Shop at Titagarh, West Bengal, is equipped with 2.5T and 1.0T capacity Drop Hammers, 300 Kg. and 400 Kg. Pneumatic Hammers, four nos. Dedicated Oil Fired Furnaces of 300 Kg./hr. to 600 Kg./hr. capacity, and adequate number supporting machinery like Band Saws, Trimming Presses, Welding Machines, Gas Cutting Sets, Air Compressor, etc. necessary for efficient forging operations. For material handling, we have Fork Lift and Mobile Crane. We, also, have at our Forging Shop one 1 Ton/Charge capacity Bogie Hearth Type Heat Treatment Furnace which is under rectification at the moment. Therefore, for the time being, we have exclusive tie-up with Aptech Enterprise and IRC Industrial Research Consultancy (P) Ltd, both at Balitikuri, Howrah, for our heat treatment and testing requirements.

Our Machine Shop at Balitikuri, Howrah is equipped with complete line of metal removal equipments including turning, milling, drilling, polishing, welding, etc., along with testing equipments to manufacture top quality carbon steel forged flanges and the necessary die for forging of flanges. This facility also contains all necessary instruments and equipments to support these operations including work holding and cutting tool needs.

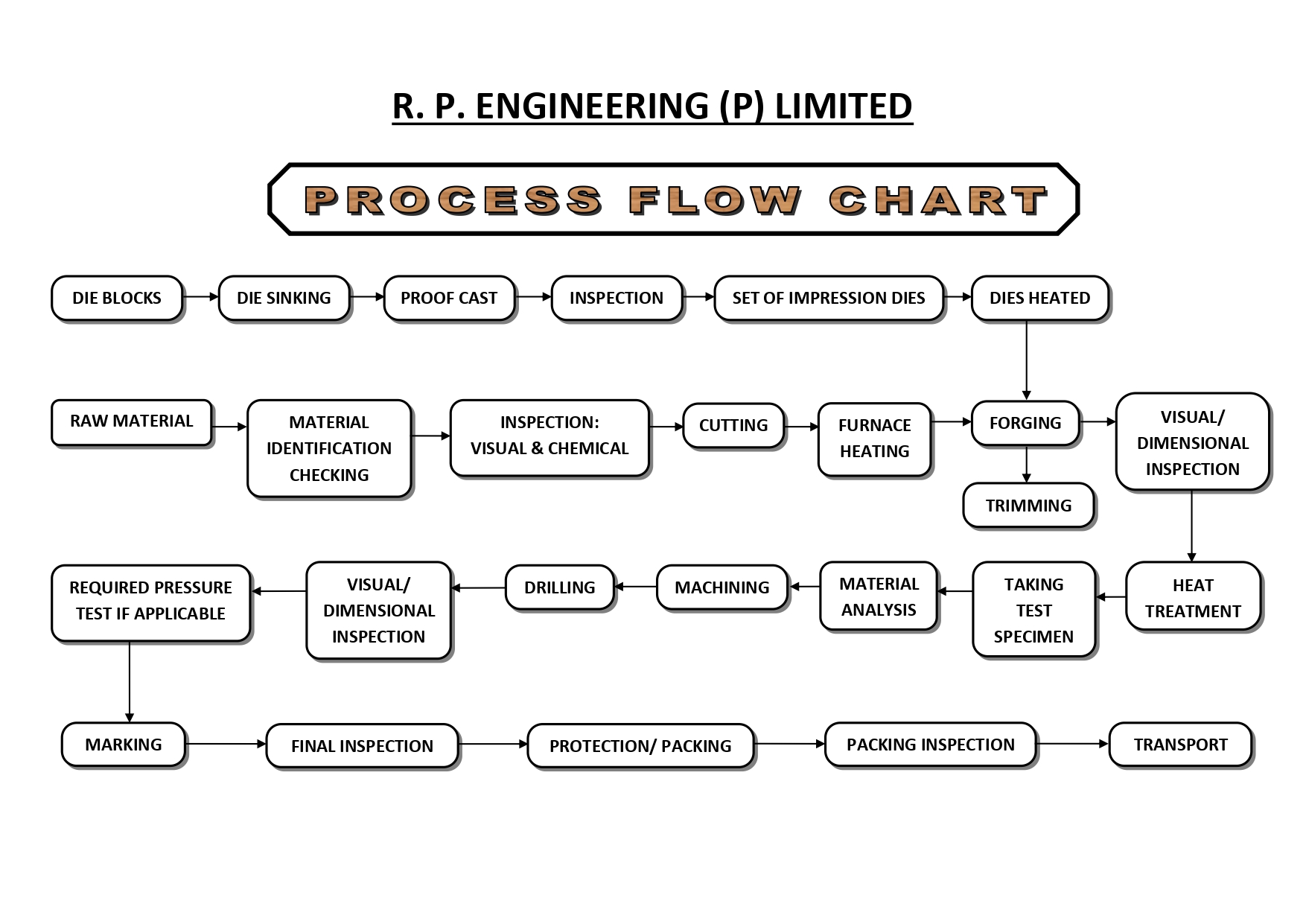

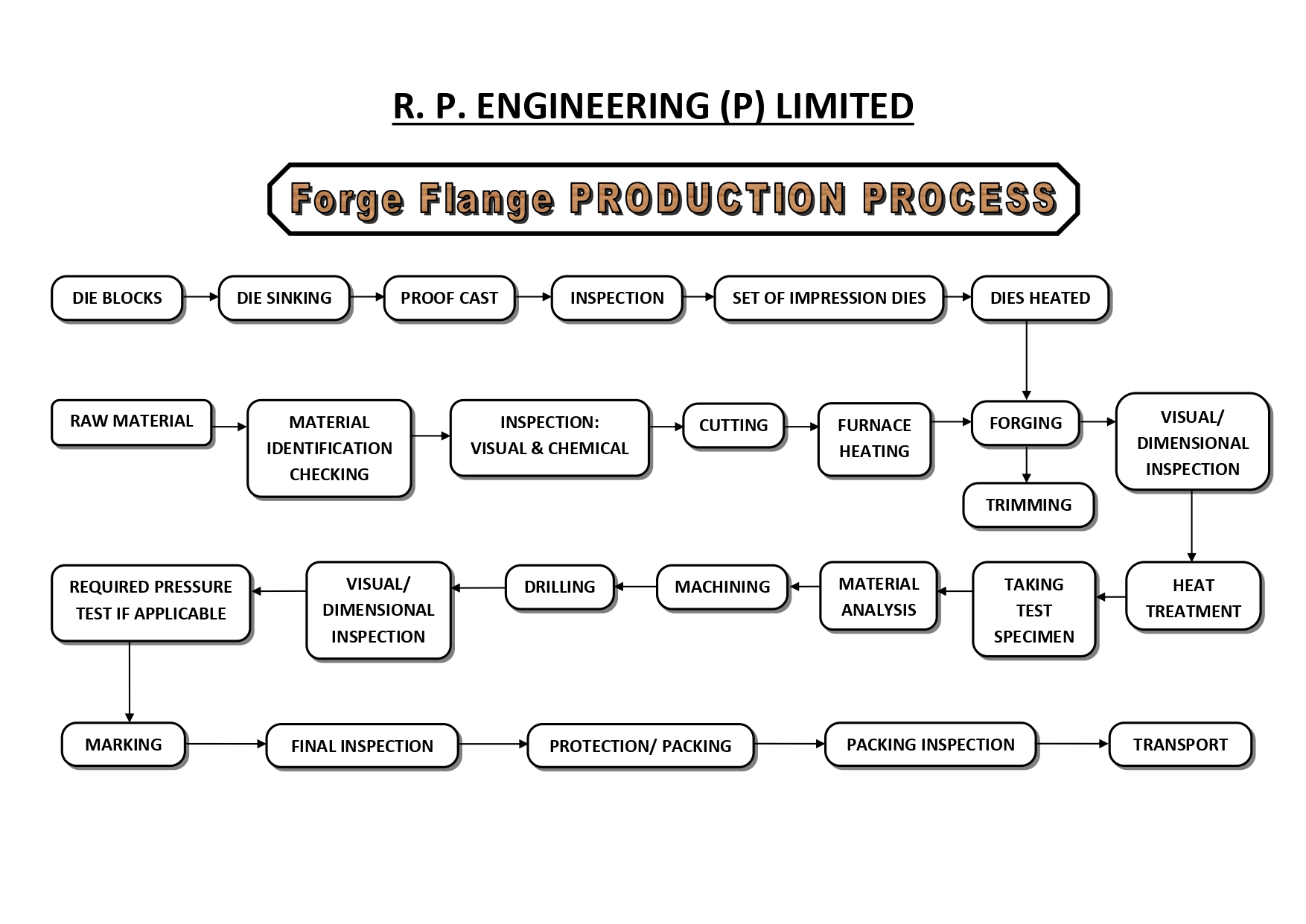

We enclose a Process Flow Chart of Forged Flanges from which our standard stages of manipulation of raw materials, from receipt to dispatch may be noted. At each stage of production, the traceability of raw materials and necessary quality control measures are ensured.

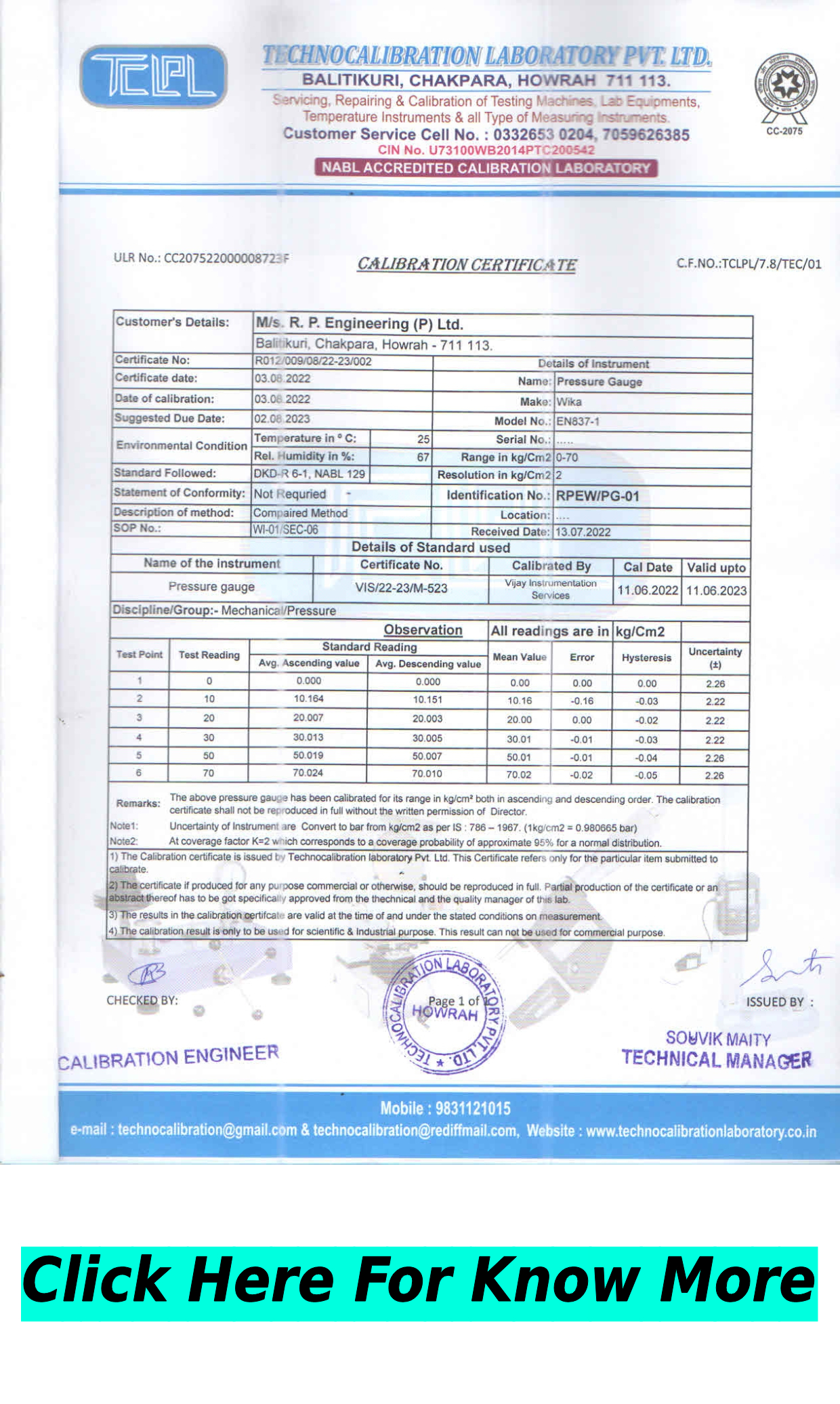

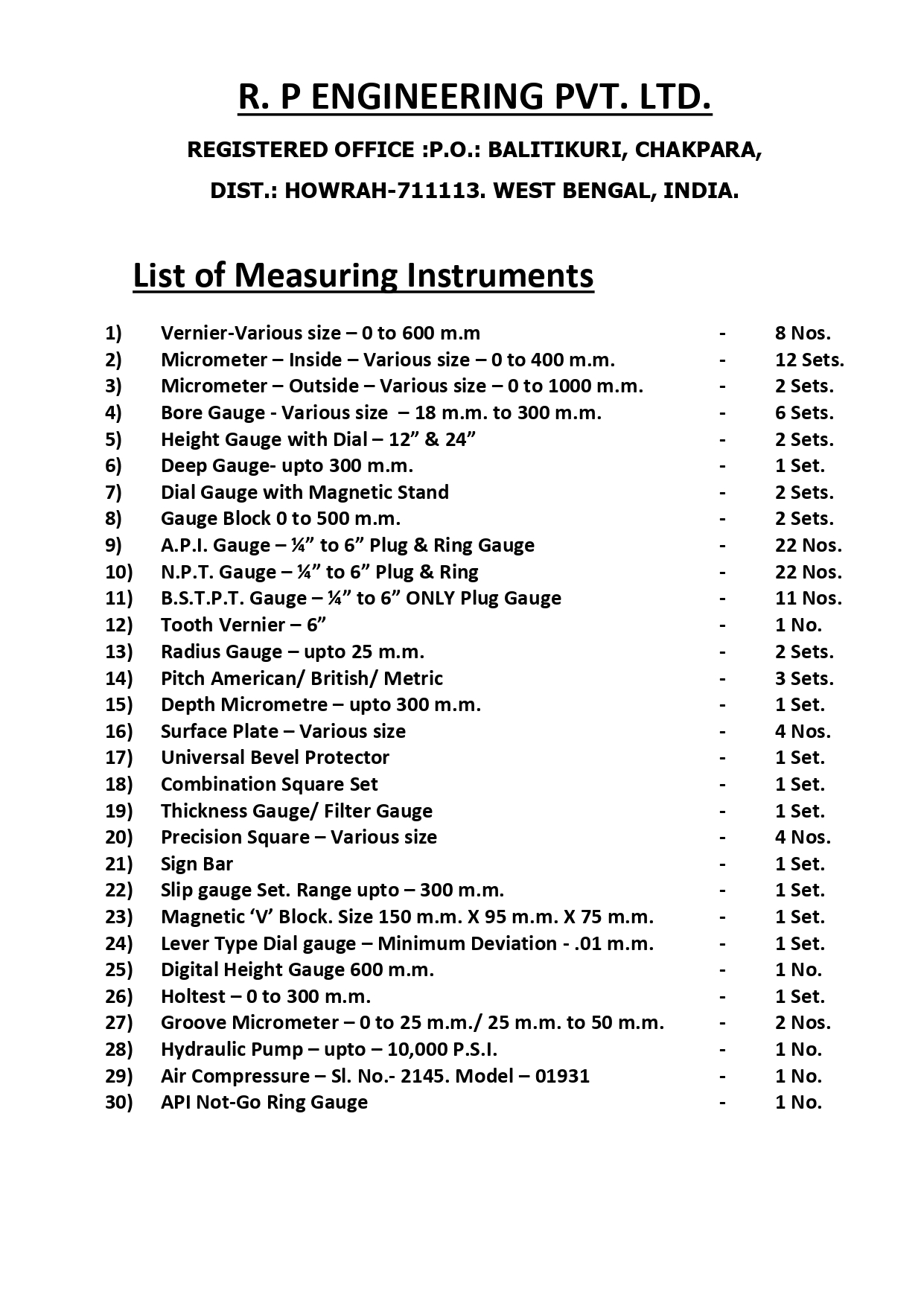

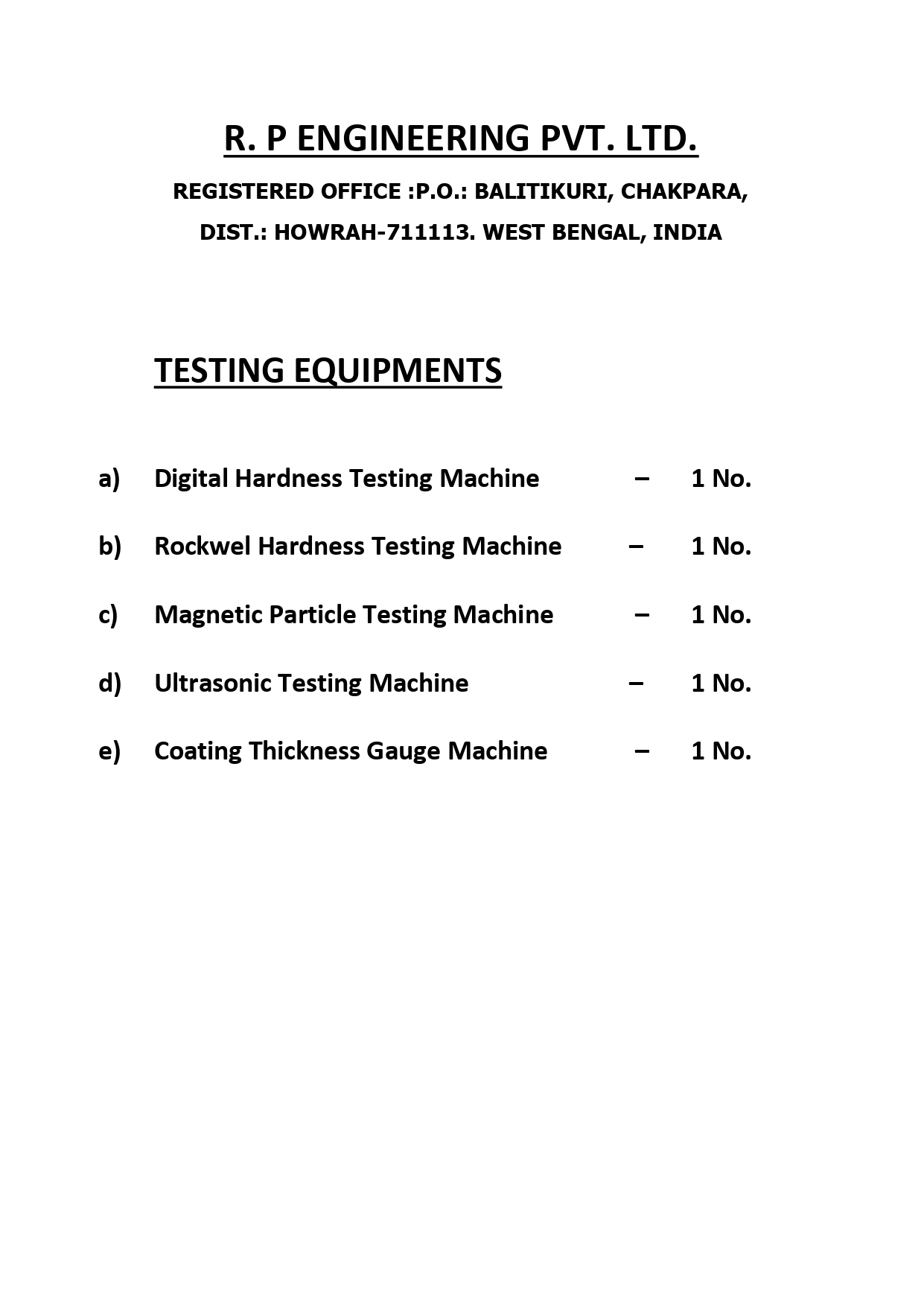

Inspection Equipment / Testing Facilities :

Various standard of ANSI, API, ASTM, ASME,B.S., IS, DIN, etc. in respect of materials as well as dimensions and as per special designs of clients. various Forging components and Open & Close Die Forgings.

Standards Followed :

1. Hydraulic testing equipment.

2. Dye- penetrant testing facilities.

3. Hardness testing machine.

4. Chemical/Physical/Ultrasonic/Radiogarphy

/Magnetic testing and all examinations are done outside by reputed laboratories like Industrial Research Consultancy (Pvt.) Ltd. ( I. R. C. ), Balitikuri, Howrah - Amta Road,Howrah - 711 113 located very near to our works as per clients recommendation.

Raw - Material :

All the raw materials are procured from manufacturer like SAIL /TISCO/ MSPL / Importer or through authorized agent / dealer along with Mill T. C. Before taking the materials in stock inspectors inspect each piece and co-relate the identification marks according to Mill T.C. We maintain the register to record the details of above for each material.

Heat Treatment Records :

For each heat treatment charge a heat number is provided and all pieces in one particular charge are marked with same heat no. register is maintained to record description of items, size and quantity of each item, for each H.T. charge with identification marks and heat no. above particulars are also recorded on time-temp. Graph chart for reference.

Final Inspection Report :

All items are subject to final inspection before it is offered to inspection agency for final inspection. This Report Covers :

(a) Dimensional check result

(b) Hydraulic test result

(c) Thread check with thread gauge result (Plug / Ring)

(d) All earlier in process test records.

(e) Heat treatment chart / certificate

(f) Visual check with remarks

(g) Dye penetrant test result with remarks if required as per P.O.

(h) Ultrasonic test result with remarks if required as per relevant P.O.

(i) If any other supplementary non-destructive test is specified in relevant P.O.

Material Test Certificates :

These are the final documents covering all the test results obtained while carrying out the testing as required by client. These certificates are being submitted to the clients if required by them.

Quality Assurance Programme for fittings :

We manufacture and supply all products in accordance with strict quality procedures. Total procedure is controlled with the aid of detailed quality assurance programme supported with all the necessary records and test certificates.